There are a whole lot of areas on a mountain bike, particularly a full suspension mountain bike, that require a good quality grease. And what’s more, depending on the component, you may want to use a different type of grease.

Let’s take a look at all the different types of mountain bike components that need grease – and what our options are as far as the best mountain bike grease for that particular area of our bike.

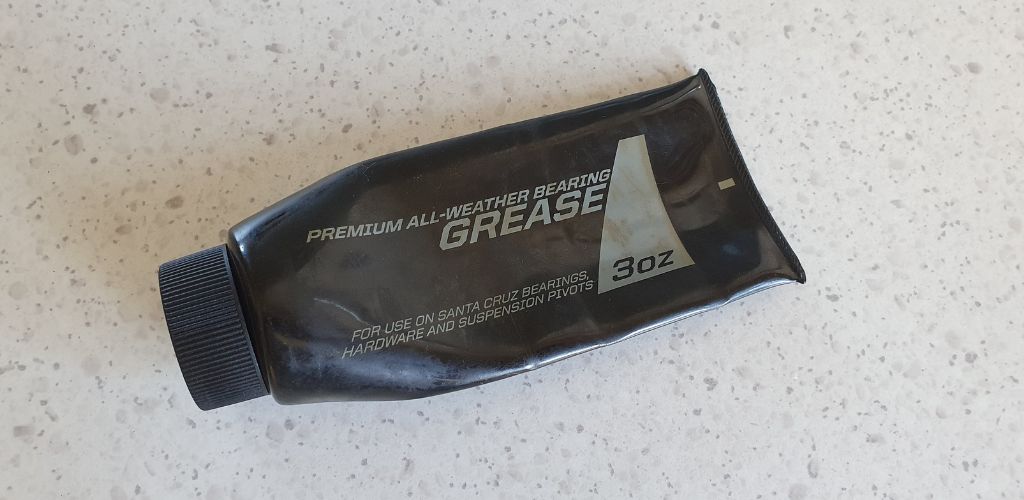

Fun fact – I actually use my tube of blue Santa Cruz pivot grease for many different areas of my mountain bike beyond just the pivots (for better or worse).

What types of grease do mountain bikes use?

There are a lot of different types of grease that get used when assembling (or maintaining) a mountain bike.

When choosing the best types of grease for a mountain bike, it’s important to consider the specific needs of different parts of the bike.

Different greases offer various properties like water resistance, corrosion protection, and friction reduction.

Here are some of the best types of grease commonly used for mountain bikes:

- Lithium-Based Grease: This is a popular choice for general-purpose use on a mountain bike. It provides good water resistance and is effective in a wide range of temperatures. It’s great for bearings, suspension pivots, and other moving parts.

- Teflon/PTFE-Based Grease: Teflon-enhanced grease offers excellent lubrication and is highly resistant to water and heat. It’s ideal for areas like pedal threads and wheel hubs. Its superior friction-reducing properties make it a good choice for high-stress areas.

- Calcium Sulfonate Grease: Known for its exceptional water resistance and excellent mechanical stability, this grease is ideal for wet or muddy riding conditions. It’s great for wheel bearings and other areas prone to water exposure.

- Synthetic Grease: Synthetic greases are designed to provide superior performance over a wide range of temperatures and conditions. They are often more resistant to breakdown and oxidation, making them suitable for high-performance applications.

- Marine Grease: While not specifically designed for bikes, marine grease is extremely water-resistant and works well for mountain bike applications where moisture exposure is a concern, such as in wheel bearings and suspension pivots.

- Anti-Seize Compound: Though not a grease per se, anti-seize is important for threaded connections such as pedal threads and bolt threads, providing protection against corrosion and seizing.

- Assembly Grease: This is used for components that require disassembly and reassembly, like headset bearings and bottom brackets. It’s designed to stay in place and not squeeze out under pressure.

- Carbon Assembly Paste: Specifically for use with carbon fiber components, this paste is not a traditional grease but is crucial for preventing slippage and over-tightening of carbon parts.

So we should just coat the entire bike in grease?

No. Definitely not! 😀

Remember that while grease is essential for maintenance, it’s important not to overuse it, as excess grease can attract dirt and grime, leading to wear and tear.

Always clean the area before applying new grease.

Also, certain areas of a mountain bike, such as chains, are better suited for specific lubricants rather than grease.

Always follow your bike manufacturer’s recommendations or consult with a professional mechanic for the best results.

What areas of a mountain bike need grease?

Greasing and lubricating a full suspension mountain bike involves different areas, each requiring specific attention. Here’s a breakdown of the areas that typically need grease rather than lube:

- Suspension Pivots: These are critical points in a full suspension bike. They allow for the movement of the suspension system. Grease is used here to ensure smooth movement and to protect against wear and corrosion.

- Headset Bearings: The bearings in the headset, which enable the front fork to rotate smoothly in the frame, should be greased. This prevents grinding and ensures a smooth steering experience. In my experience a headset bearing will eventually always wear down and get kind of rough and crunchy in its movement. They have a tough life.

- Bottom Bracket Bearings: The bottom bracket, which houses the bearings that the crankset spins on, should be greased. This is essential for smooth pedaling and to protect the bearings from wear and contamination. The bottom bracket bearings are another area of the bike that deal with all sorts of rotational forces, directional impacts, ingress of water and grit, and everything that you don’t want a bearing to have to deal with every day.

- Pedal Threads: The threads where the pedals attach to the crank arms should be greased. This facilitates easy pedal removal and installation, and prevents the threads from seizing or corroding.

- Seatpost: The interface between the seatpost and the bike frame should be greased (unless it’s a carbon frame and seatpost, in which case a carbon-specific compound is used). This helps prevent the seatpost from seizing in the frame. Here we are referring to the actual seatpost in the frame of the bike, and not the moving parts of a dropper seatpost.

- Wheel Hubs: The bearings within the wheel hubs should be greased. This ensures that your wheels spin freely and smoothly, and helps protect the bearings from wear.

- Suspension Linkages: Any linkages in the suspension system should be greased to maintain smooth operation and to protect them from wear and contamination.

- Bolt Threads: Various bolt threads on the bike, such as those on the disc brake mounts, derailleur mounts, etc., should be lightly greased to prevent seizing and to make future adjustments or repairs easier.

- Quick Release Skewers or Thru-Axles: The cam mechanism of quick release skewers and the threads on thru-axles benefit from a light application of grease.

It’s important to use the right type of grease for each application and to avoid over-greasing, which can attract dirt and grime.

Also, regular maintenance and inspection are key to ensuring that your bike remains in good working order. Always refer to your bike’s manual or a professional mechanic for specific maintenance advice for your model.

So what are the best mountain bike greases?

Here’s a list of popular mountain bike grease products, their uses, and manufacturers:

- Finish Line Premium Grease: Designed for high-pressure applications, this grease is excellent for areas like bottom brackets and headsets. It’s known for its resistance to rust and corrosion but is not suitable for carbon fiber bikes.

- Phil Wood Grease: This grease is praised for its ability to repel dirt and dust and is excellent for bearings due to its waterproof properties and smooth texture. It’s a great choice for pedal threads, wheel hubs, and suspension pivots.

- Park Tool HPG-1 High Performance Grease: Suitable for extreme temperatures and carbon fiber components, this grease is ideal for headsets, bottom brackets, and hub bearings. Its water-resistant quality makes it a good choice for wet conditions.

- Bel-Ray Waterproof Grease: Known for its versatility, this grease can be used on various parts of the bike, including bearings and pivots. It’s waterproof and can withstand high temperatures, making it suitable for diverse conditions.

- Finish Line Ceramic Grease: This grease uses ceramic and Teflon fluoropolymer to reduce friction. It’s excellent for bearings, providing long-lasting lubrication and protection against rust and corrosion. This grease is also safe for carbon fiber bikes.

- Permatex White Lithium Grease: An all-purpose lithium grease ideal for metal-to-metal and metal-to-plastic applications. It’s great for bottom brackets and other larger bearings but may be too dense for smaller components.

- Shimano Dura-Ace Grease: This grease is used for its heat tolerance and waterproof qualities. It’s suitable for bearings and helps in maintaining smooth operation in various components of the bike.

- White Lightning Crystal Grease Biodegradable: A non-toxic, biodegradable grease that’s clear, odorless, and safe for carbon fiber bikes. It’s suitable for wheel bearings and other bike parts, but may wash off quicker than other greases.

- Phil Wood 3-Ounce Grease Tube: This is another variant of Phil Wood Grease, known for its water-repelling ability and suitability for carbon fiber bikes. It’s ideal for wheel bearings and known for its longevity.

- Maxima Waterproof Grease: Marketed for motorsports but also suitable for bicycle bearings, this grease is budget-friendly and high-quality. It’s known for being durable and effective, though there have been reports of poor packaging.

Each of these greases has specific properties that make them suitable for different parts of a mountain bike. It’s essential to select the right grease based on the specific application and the bike’s material (especially in the case of carbon fiber components).